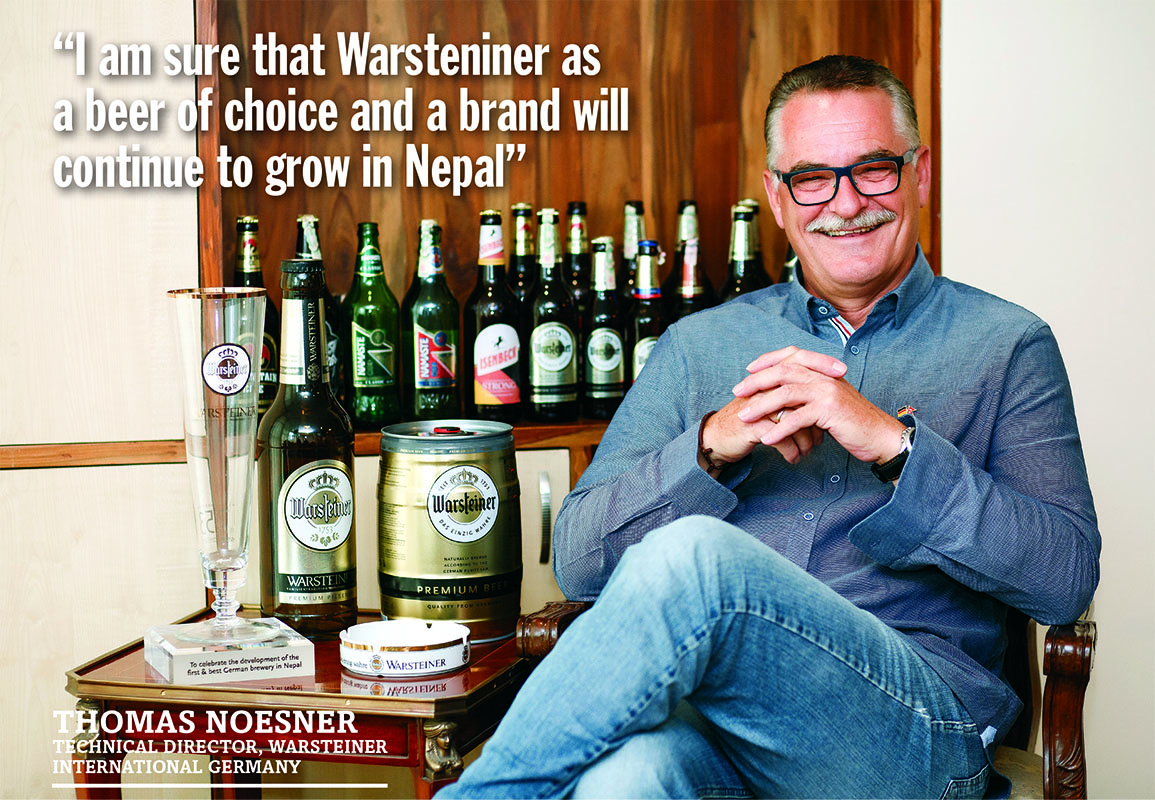

Thomas Noesner

Technical Director, Warsteiner International Germany

A lifelong brewer, Thomas Noesner first started brewing as a student during his holidays. He took the classical route of working as an apprentice for three years in a brewery that basically meant that he was brewing the same time he was attending schools where 90% of his education is connected to the brewing technology. He obtained his degree as a Brew Master from the University of Weihenstephan which at the time was known for the prestigious brewing diploma. Since 1976, he has been heavily involved and working for several breweries in Germany.

Noesner has been with the Warsteiner Group since 1987. He has held the responsibility of working in various locations and breweries operated by the renowned beverage company. Today, he is the Technical Director at Warsteiner International Germany and has held the post since 2008.

Avant Shrestha of Business 360 caught up with Noesner during his visit to Nepal and discussed his remarkable career with the renowned beer company, and Warsteiner’s integration and performance in the Nepali market.

Could you share with us about your role as a Technical Director for Warsteiner International?

Well, I have been in this role since 2008 and in simple terms, basically I am responsible for all the brewing, the bottling and the packaging affairs outside of Germany for our worldwide distribution. The countries that I am currently working with at the moment are Argentina, some parts of Ukraine, Great Britain and West Africa.

Additionally, I am responsible to conduct some brew checks in Warsteiner Group in Germany but that role is reducing more and more because the license business is growing and my commitment is not required there. But overall, my major job and my main target is to maintain the same quality worldwide.

Jawalakhel Group of Industries claims to have one of the most advanced breweries in the region, how would you rate it?

Well, I would agree with their claim. It definitely is a top standard brewery. And I am happy to say at the moment they have some modern equipment and as a result the brewery is doing really well.

We have been involved in the process from beginning stages. We were working together when the idea about constructing a brewery by Raj Brewery was incepted and I have to say that was a big advantage for all parties. In the initial stages we could always conduct routine checks and cross checks and monitor the standard of the technology and the quality of the equipment we were using for the brewery. Plus we have very dedicated and engaged brewing staff in the brewery who make all the difference. So, when you combine all these elements, the result of the beer is the real proof that this venture was a really good decision and the brewery is topnotch.

What in your opinion are the three qualities that cannot be compromised for making a good beer?

That is very simple. First of all, it is the raw material. Raw material has an incredibly high impact and is one of our major focus. Secondly, it is the equipment of the brewery. And lastly, the passion of the staff; their ability to run all the equipment and technology. And, from what I have observed, the standard and dedication in Nepal is very good. I was very doubtful in the beginning to have a very young team that were not experienced, but in a very short time they really became real brewers and this is really great to see.

You came here in March 2018 and spoke about the logical and technical challenges. Are you happy with the standards and procedures being maintained?

Yeah, of course. In-fact they have definitely exceeded my expectation. I did not expect such a high standard and level. Our major focus is to maintain extremely long flavour stability. But there are lots of challenges for brewers all over the world when it comes to maintaining the flavour stability because as soon as you start bottling beers, they are no longer under your control.

There are lots of factors that affect the stability, for example, light and temperature influence the taste as well. And you can only make adjustments in the brewery to make it as stable as possible. And I am happy to say that the Nepali brewery and the Warsteiner brewery are being able to maintain the biggest flavour stability we have. So once again that is of course because of the equipment. Raj Brewery has always been open to upscale and introduce modern technology and we are thankful that currently we have positive results and quality here. Of course, if we are able to mitigate some of the financial burden here, it would be better but as far as the stability of the beer goes, I am extremely satisfied.

What kind of quality systems and control testing do you have in place for production at the brewery here?

Maintaining the quality of equipment is important because the equipment is already a kind of quality control when you combine it with a well equipped lab. And the laboratory here in the brewery is on par with the brewery in Germany, if not better. But I believe the key ingredient is the combination of equipment and the knowledge and the experience of the brewers. What we could already do here is that we have online control systems which are permanently checking some parameters combined with good equipped lab and assisted with a high frequency of quality control. I wouldn’t say it is a certain type of quality control system; it is basically a combination of them all.

Could you briefly explain to us about the German purity law and the role it plays in quality control in both Germany and Nepal?

There is no difference between our standard protocols in Germany to that of Nepal. The quality control methods are identical. We strictly abide by the purity law which basically means that we only use malt, hops, water and yeast and even the yeast is selected over decades in our brewery. Therefore, it is highly important for us to have our yeast here. We would never do a license without our yeast and the rest is identical. We do not use any chemical and additions; we do not work with sugar.

It is the oldest food law in the world and we are strictly keeping up to its code of conduct. My worry was if we would be able to maintain the stability of the beer in hot countries like Nepal. However, I can tell you that the stability of the beer works better when you do not add any unnecessary additives in the brew. As a result, the proof is Nepal again, the stability is so high and we are so happy with the quality over here. To be honest, I was a little bit proud about that. And it was all because of the effort of the team; the team is wonderful.

Do you have to change any iteration for Nepal?

Basically we are identical - Raj Brewery here and the Warsteiner brewery in Germany. The raw materials that we use here such as the malt is from Europe. Raj Brewery only supplies malt with our specification. Suppliers are briefed that they get the same quality as what they get in Germany.

For hops on the other hand, we have to put in a lot of efforts, especially for the Warsteiner Brewery and for our brewery here. We do not supply hops from normal dealers. We make sure that we select the best quality of hops on the field where we have our experts monitoring the best quality of hops and we conduct checks on the plant and then we bring it to our laboratory. We observe the entire production for the hops until it is in our packages. Once again, Warsteiner and German beer are always hoppy and the more hoppy the better the beer is; this is very important to us.

What should one expect when enjoying Warsteiner?

The taste (laughs). To be honest, it is the taste for sure. Well, German beers are bit hoppier and that is something one should expect. Of course, Warsteiner is a German style, and one can appreciate that Warsteiner is well balanced. It is not only harsh, it’s a bit bitter, and it is not only sweet but it is balanced. Our main target is to balance out our hoppiness with the malty body and that is something I believe our consumers should expect and be able to enjoy.

Of course, when you come to a market like Nepal, where the hoppiness in the beers are extremely low, people generally get curious, some get critical and some love it which I believe is a totally normal process. But then again, I think we are on the right track. People who prefer Warsteiner are continuously growing; although not as fast as we expected, but we can see it clearly going up.

Are you happy with the response that Warsteiner is getting in the Nepali market?

Yes, of course. When a new product enters the market, people often get curious but at the same time it takes time for people to get used to the new product. But I am convinced the quality and the digestive ability of our beer will convince people over time. And I am sure that Warsteniner as a beer of choice and a brand will continue to grow in Nepal.

As an experienced brewer from a country that has perfected beer, do you think Nepal can reach the level Germany has in gaining international recognition?

I would say that Nepal is not far from the world market. I do not see that there is a big difference in Nepal and the international market anymore as Nepal already has really good beers. However, it’s according to individual perception to say what a good beer is and what a bad one is because everyone has different taste.

But since each human being has a different perception, it will be the reason why a wider variety of beers will continue to increase.Currently in Nepal, the growth of the Strong Beer is increasing but I believe other varieties will slowly but eventually make an entry in the market. The more beer options in beer the better for the market. As for Warsteiner, our job is to make our product suitable to the people who decide to consume them.